The KFB2.0 3D printer controller board

I’m on my 3rd KFB2.0 now (for 3 different printers) and I like these little boards. For the price you pay for them, you really can’t go wrong with them. I found these on Amazon.com for less than $20.

It has everything on it, the RAMPS 1.4 has with the Arduino chip integrated on the board but it’s only a third of the height of a full RAMPS with Shield and LCD adapter attached.

Some other advantages over the RAMPS 1.4:

- It can take 24V

- There are two continuous voltage outputs 5Volt and 12Volt

- It has the ICSP pins which allow you to go with TMC2130 without jumping through hoops for competing pins

- It has a 4th controllable 12Volt output, which frankly I haven’t figured out yet.

It uses all JST-XHP 2.54 connectors which I think hold a bit better than the loose RAMPS 1.4 connections but it does mean you may have to do some crimping of your own.

The only major downside: It has NO Documentation, at all. I figured out most of it and tried to put it all together here.

It wasn’t overly difficult. It mimics the RAMPS 1.4 and all pin outputs are the same.

Getting Started

In the wiring setup described below I use the following parts. I am an Amazon Affiliate so you would support me by clicking and buying through these links.

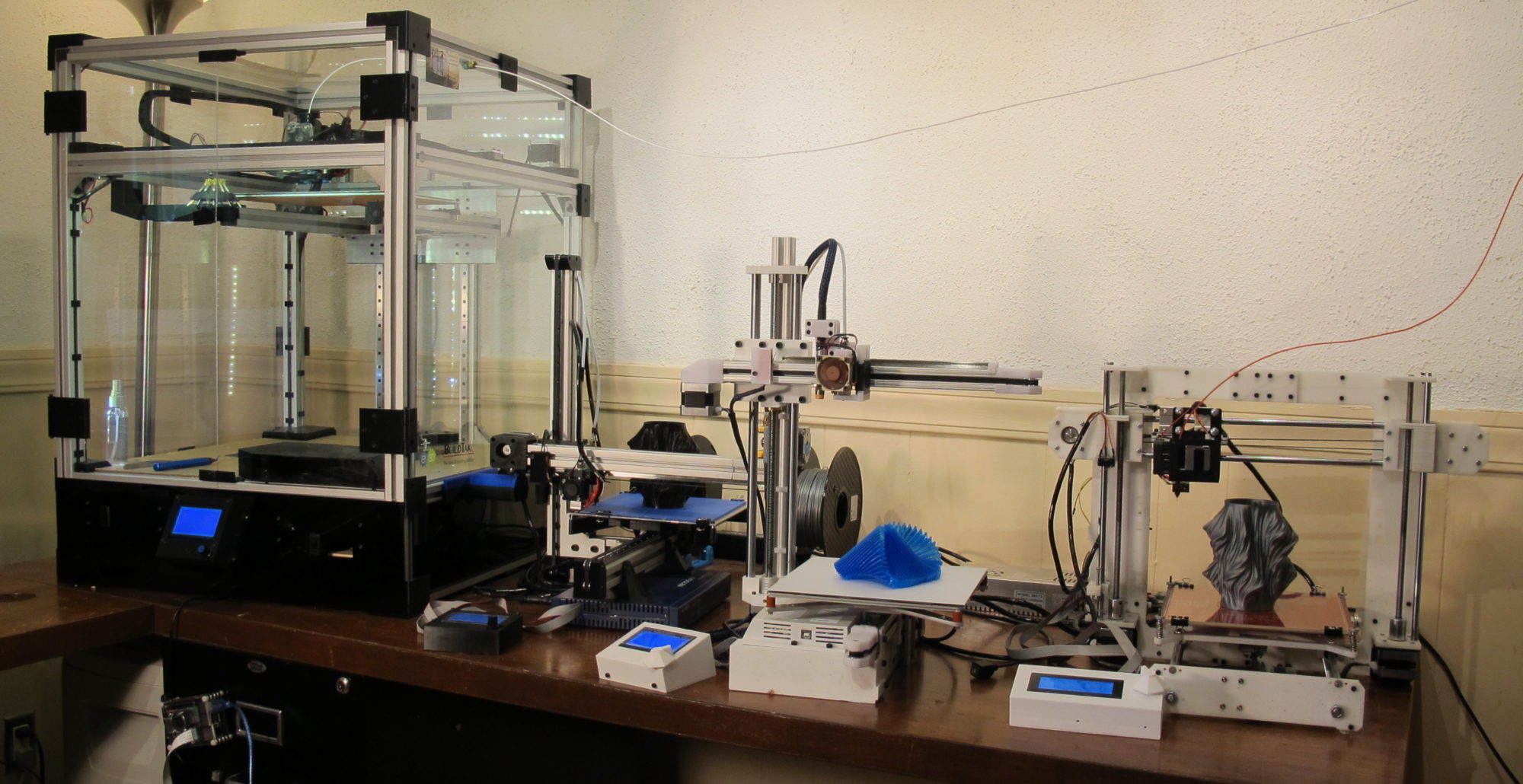

I have used the KFB2.0 board on 2 of my printers. The C3Dt c and the low budget (build on a Netgear Case) Cantilever and am pleased with the way it operates.

The KFB2.0: $18.59 https://amzn.to/2G7xQB8

Here’s a list of all the items I have attached to the KFB2.0

Nema 17 1.7A (5 pack) $48.99 https://amzn.to/2pGlEwO

Mk8 Extruder:

- Full direct extruder $36.99 https://amzn.to/2pIHEr1

- Extruder Frame only $8.99 https://amzn.to/2pFXjHE

V6 Hotend (12V): $18.99 https://amzn.to/2GfIt0U

For end stop control you can go with two different options:

- The fully wired Limit switch (with cables): $7.98 https://amzn.to/2pIIEvh

- The simple Micro Switch: $8.99 https://amzn.to/2IQGt0u

Stepper Cables: $8.59 https://amzn.to/2I56yHY (JSP HX2.54, which fit the KFB2.0)

12V/30Amp Power supply 19.98: https://amzn.to/2pGXlPD

Heated Bed $31.99 https://amzn.to/2IU6NHp (optional but I will explain the wiring)

Thermistors $8.99 https://amzn.to/2pG01vW

LCD 12864 $14.99 https://amzn.to/2IU7LU3

Stepper Drivers $10.99 https://amzn.to/2I3eCZS

Fans. I’m a huge fan of the Noctua Fans. They are a bit pricier but worth the SUPER quiet:

- 12Volt: $13.95 https://amzn.to/2DWedWJ

- 5Volt: $13.95: https://amzn.to/2GbQuUk (I use the 5Volt, leaving the 12 Volt for Auto Bed Leveling)

(If you want to go with the TMC2130, I recommend getting the real deal from trinamic through Filastruder.com). Cheaper knockoffs are available here. They tend to be not that much cheaper and there some bad reviews out there.

Putting the first pieces together

Like the RAMPS 1.4, the KFB2.0 takes the pluggable stepper drivers that run the stepper motors. The cheap option is to go with the a4988 drivers or the totally awesome TMC2130 (not affiliated, but my upgrade instructions can be found here).

If you go with the a4988 driver you first need to insert the 3 jumpers in each of the diver bays.

In the image above I’ve added the pin descriptions around the middle bay. These pins need to correspond with the pins on your driver circuit board (generally found at the bottom of the board

Insert all stepper drivers and make sure all pins went in on both sides (It’s easy to miss). Once insert it would look something like this (for the a4988 drivers).

(don’t rely on the orientation of the pot meters in this image. TMC2130 and DRV8825 point the other direction. Look at the pin descriptions on the board and driver and orient accordingly).

Wiring the KFB2.0

Do not attach your board to any backing prior to wiring as all the useful information is found on the back of the board. Beyond that wiring is pretty straight forward. The KFB has the exact same pin outputs as the RAMP 1.4 and as a matter of fact, you select the RAMPS 1.4 board in Marlin when configuring the software.

The above image pretty much show all the different connections you might be making.

Your power source (either 12 Volt or 24 Volt) is attached to the XS 12-24V pins. Polarity is very important here, so make sure Positive and Negative and connected properly (there’s a + and – next to the inputs).

Connecting the Fans

As I mentioned earlier, the KFB2.0 has two continuous outputs for a possible fan. This fan would come on the moment you power up the board. It generally connects to the hot-end fan cooling the heat sink above your hot-end.

Polarity matters and fans should be connected accordingly. They generally come with one black and one red wire. Red = + , Black = –

I personally like the Noctua fans. They’re a bit pricey but it’s worth any every penny due to their quiet operation. The Heat sink fan comes on when you turn on your printer and may still on long after your print is done. With these quiet fans I can’t tell the printer is on by sound.

If you are planning on auto bed leveling, you’ll need the 12Volt output for that. In that case, I would recommend the 5 volt Noctua, leaving the 12Volt for other purposes.

Connecting the Heaters

This board has three outputs for heaters.

- Hot Bed (Heated Bed)

- Heater0 (primary extruder)

- Heater1 (second extruder)

-The Hot bed and Heater0 outputs speak for themselves. Hot bed connects to a heated bed (if you use one); Heater0 connects to the hot-end for your first extruder. They don’t care about polarity but make sure you use wire of proper gauge (14-16) as these carry a lot of Amps.

Heater1 is not as straight forward. If you have double extruders you would expect to connect the second one to this channel. This is not the case (and the only flaw I’ve found on this board to date). Output for the second extruder is sent to the Fan channel (not HEATER1). This is a problem if you choose to have dual extruder with a parts fan (then again you may end up needing more fans). I have not been able to get this to work (most of us won’t need it). I’ve tried tracing its pins back to the board but even after doing so I could not get it powered up.

Connecting the Thermistors

For each of the heated elements you use (beds and extruders) you’ll need to connect the thermistors for temperature feedback.

Generally your hot-end is shipped with heating cartridge and thermistor but for heated beds this is not always the case. You can buy them loose at Amazon for $8.99 (5-pack).

In most cases you’ll be dealing with a hot-end and heated bed in which case you connect to the TEMP0 (hot-end 1) and TEMP-BED (the bed).

Note: any preliminary testing of your electronics requires at least one thermistor connected to the TEMP0 (without software changes). It’s always handy to have a spare thermistor lying around for such cases.

Connecting the end stops

Most 3D printers only need to have the min end stops attached. Reading the min stop along with specifying the dimensions of your printer will keep your axis within the allowed boundaries. For this setup we’ll connect the min end-stops only.

There’s a variety of end stops available ranging from the simple Micro switches to the wired up Makerbot style switches to optical and inducer type end stops. For this setup we’ll look at the simply micro switches and the Makerbot style end stops.

Given that price range is very similar (you can get micro switched for pennies but they tend to come in packs of 25), the only reason you would choose one of the other is the size. The Makerbot comes pre-wired with a little circuit board but you’ll have to account for more room required.

MakerBot style End Stops

The pre-wired Makerbot style end stops have 3 wires from them. Red, Black and Green.

You may have to crimp your own wires to use a JST-XHP 2.54 3 pin connector on both ends (out of the box they come with the plain pin connectors).

Make sure the Red wire is connected to the vcc pin. Connecting them the other way around will fry your board.

Micro switches

If you choose the micro switch, it’s my experience wiring is a bit easier; you only need two wires.

Solder the wires to the two outside pins of the Micro switch and connect them to the GND and Signal pin on the ramps. These are the two pins towards the outside of the board (GND and Signal)

Since in this configuration the connection is open you will have to flip the configuration in the Marlin software to reverse the signal.

Connecting the LCD

NOTE: Several reviewers for the KFB2.0 complained about LCD connectors soldered on backwards. This requires to cut of the notches from their cables. I ‘m not dismissing this, but I’ve used 3 boards and have not found this to be a problem. I’ve seen similar complaints using different board and wonder if this could be a wiring mixup issue.

The LCD connects to the two EXP1 and EXP2 connectors on the board via the 2 flat cables that most likely came with your LCD unit. You’re LCD board will have the corresponding EXP1 and EXP2 on the back.

Conclusion

I think that covers it. The main downside of the KFB2.0 board is it’s utter lack of specs and documentation. They probably thought they would get away with it because it is so similar to the RAMPS 1.4 (with all the same pin outputs).

What I like about the board is the fact is build much more compact than the RAMPS 1.4 and in fact does act the same.

Some other advantages are an easier means of using the TMC2130 stepper drivers, 12-24volt range ad the 5 and 12volt fan outputs.

I hope this instructional post will mitigate some of the lack of documentation.

If you like what you see here or more importantly if you’ve used some of the designs/instructions I’ve shared via multiple platforms, please consider supporting me via Patreon.com. A few extra dollars a month from enough patrons would certainly help.

Become my Patron at https://www.patreon.com/Core3d_tech

Thank you!!

HI,

Can you point us in the right direction to download and install the firmware for this.

Thank you in advance

I personally run Marlin on most of my boards. You can download Marlin here: http://marlinfw.org/

installation instructions can be found here: http://marlinfw.org/docs/basics/install.html

Here’s my video on installing and configuring Marlin for my 3D Printer: https://youtu.be/J1mVPmvX2XA