This all started with 3 THK linear rails I found on eBay. SR15 Genuine THK at 1630mm long. Price $450. I added it to my eBay list and went back and forth probably 50 times before I went ahead and clicked Buy Now.

3 linear rail = Delta

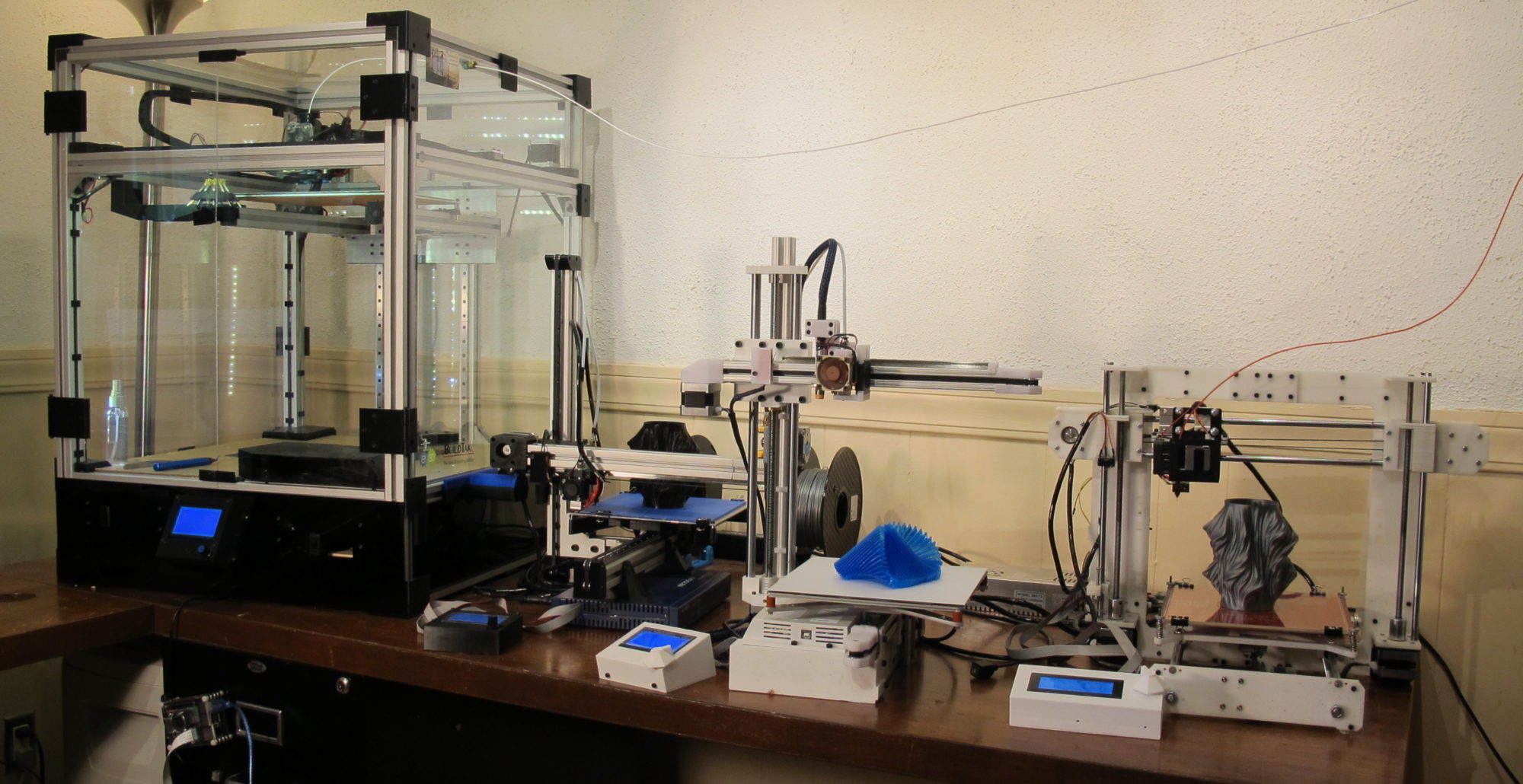

I’ve now designed and implemented 4 printers. One I3 Clone (to get my feet wet), a CoreXY and two cantilevers (C3Dt/n and C3Dt/c). This is, and will remain, a hobby for me so I like to try new things. Delta Kossel, is something I hadn’t done yet, so regardless of it’s pros and cons (much debate on this); a Delta it is. A BIG delta with one additional feature that I’m pretty hasn’t been done before (one I’m gonna keep to myself for now but all will be revealed at MRRF2019 (Mid West RepRap Festival 2019).

Here’s a clue about the new feature (x3)

Specs

For this printer I wanted to go big foremost but I also wanted to get good parts. I’m limiting myself this time in getting stuff directly from China).

- Build volume: 320mm x 1220mm

- Hot-end E3D V6 (Threaded for Effector)

- Controller: Duet Wifi

- LCD: PanelDue 7″ touch screen

- Delta Smart Effector (with touch sensor homing)

- Drive: Nema 23 for X Y and Z, Nema 17 for Extruder

- Heated bed 110V

- Linear Rail SR15 (THK)

Given Nema 23 and THK rails, speed should be possible (Although, I’m not a true believer of 3D printing and speed).

Current state and first impressions

I’m now about 80% into the build and I’ve already learned a few valuable lessons.

Aluminum extrusion alone won’t do it

I’m using 4040 Aluminum extrusion at 2000mm height. I’m using brackets I found on ebay that accomodate this size but these aren’t very strong. I quickly learned, the frame alone does not offer enough support to make this a stable printer. Regardless of the weaker corner joints, simply the length of the extrusion introduces a torsion that is problematic. I’ve bolted 2 of the 3 frame supports to my wall and built-in desk which has solved this issue. I’m not entirely sure how to handle this when showing at MRRF2019. I wonder if tripod legs from the middle down would help.

Delta Printers by nature sacrifice a lot of height

Even though the linear rails are 1630mm long, I don’t think I’ll achieve more than 1220 Print height. The effector arms simply take up a lot of space. I will be using 360mm long effector arms ( I believe the least I can get away with with a 330mm bed) so at most there’s 1630-360= 1270mm

add to that the actual height of the effector and hot-end at 58mm that leaves 1210mm (All this time I thought it was 1220, dang, lost another centimeter).

Lots of wire

At the moment the plan is to run the hot-end wiring though the top of the printer (might might change that idea) which means lots of wire. The Delta Smart Effector hooks up to 18 wires

- 2 wires for heat sink fan

- 2 wires for hot-end

- 2-4 wires for thermistor

- 2 wires for parts cooling fan

- 4 wires for Z probe

- 4 wires for Extruder (yes I’m planning a flying extruder, only inches above the hot-end)

All these 18 wires have to make it all the way to the top of the printer (say 2,000-300= 1,700mm) plus some way down again to the controller board (let’s say another 1,000mm). I’m not putting the electronics in the top of the printer because I can’t reach it (duh). I’m not putting it below the bed because of the 110V bed heating pad.

Then there is the 3 wires for each end-stop (X,Y and Z) at let’s say 1,400mm

The 3 stepper motors at the bottom of the printer. I decided to put them at the bottom as three Nema 23 motors are quite heavy (better have a heavy base than top). so there’s another 4×3 wires at another 1,400mm.

4 wires for the heated bed (2 power, 2 thermistor) at 1,000

So we’re looking at a total of at least:

(14*2,700)+(3*3*1,400)+(3*4*1,400)+(4*1,000) = 71,200mm = 71 Meters of wiring.

right now practically all wiring is 22 awg (including hot-end wires) and I hope that will do (of course not the 110V wires).

Duet is pretty awesome

I’m still not entirely over the guilt of moving from marlin to RapRapFirmware but the documentation provided by Duet is very comprehensive and has yet to let me down.

I purchased the PanelDue 7″ and in hindsight that may have been overkill. You basically get a slimmed down UI from the web interface which really is all you need.

The Delta Smart Effector is a nifty little device. One wired up (as seen in the image), I can see it easily swapable for another (basically two connectors and a bowden tub).

Where am I now

As of this writing I’d say 80% of the printer is done. Frame is done, I have Duet Wifi wired up. Effector is in place, Hot-end heats up.

I Still need to add an extruder. I’d like to get my hands on a BondTech BMG but I’ll need to help from them (or a donor). If not I’ll probably start out with a simply MK8 implementation.

Well there you have it. The Delta build to date. The current price tag is now up to $1,400 and climbing. If you have the means to support me, please check out my Patreon page at https://www.patreon.com/Core3d_tech

Stay updated on my tweets at @Core3d_tech or on facebook at https://www.facebook.com/Core3D.tech/

My next post will probably show the first test prints (or at least calibration).