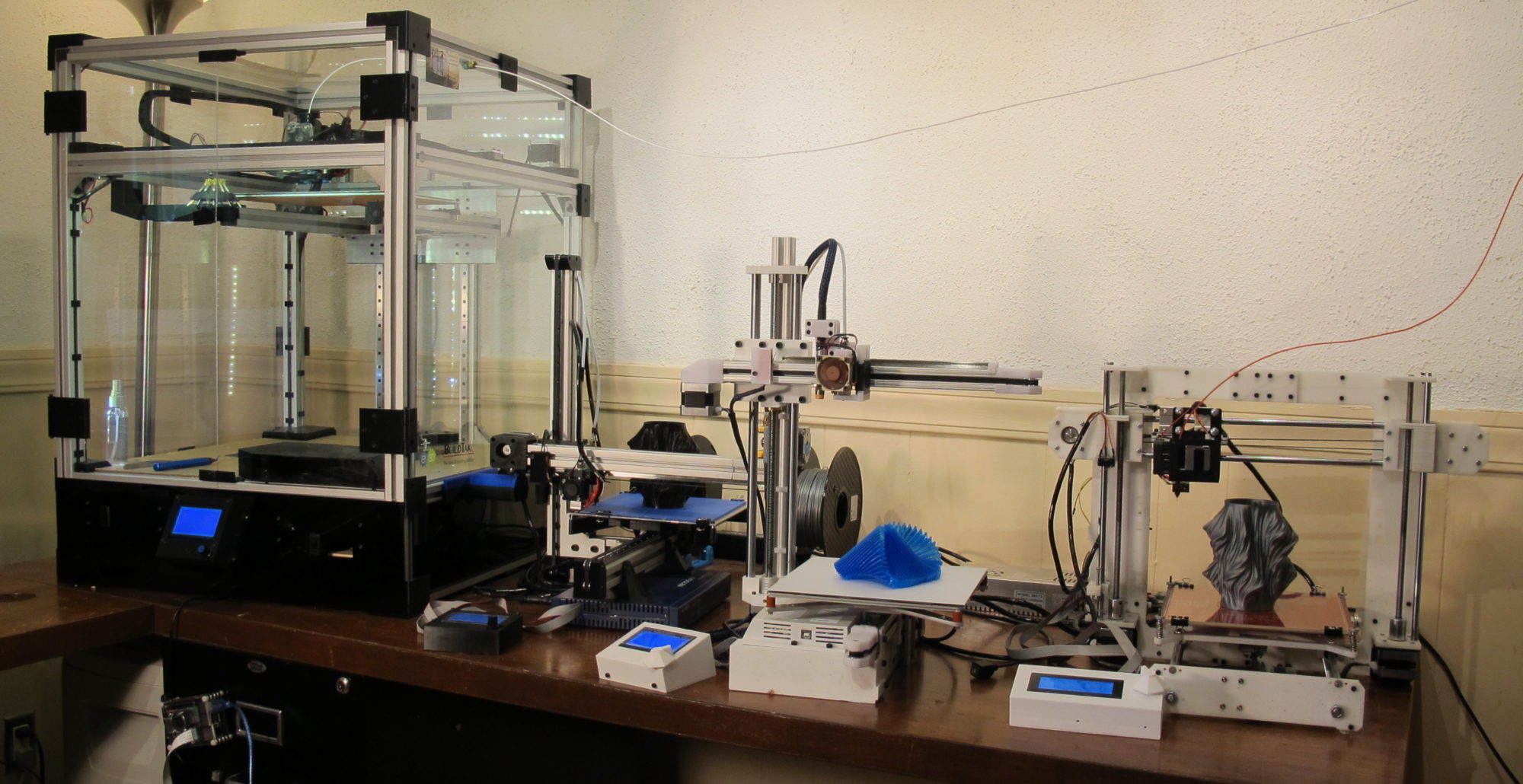

The Core XY I built and have been gradually upgrading is a beast but it still runs on 12 volts. It runs on a plain RAMPS 1.4 recently upgraded with TMC2130 stepper drivers.

It’s possible to upgrade a RAMPS 1.4 to 24 Volt but it seems easier to go with a 24 Volt board off the shelf. In my case a KFB2.0 (very close relative to the MKS GEN L).

Why upgrade? Well, from all I’ve read, it provides more torque to the stepper motors and it also seems that TMC2130 don’t run well in spreadcycle with 12Volt. Supposedly, the Spreadcycle should get a bit more quiet with 24 Volt.

What will change

Power Switching Unit

Obviously the existing 12 Volt Power switch will be replaced with a 24 Volt one. $19.98 on Amazon: https://amzn.to/2JevH8i Other than the Sticker on the outside stating 24V/15A instead of 12Volt/30A, there is remarkable little difference between the two units (both outside and inside).

Once I ordered the 24Volt power switching unit and hooked it up, I noticed the cooling fan came on immediately. That’s annoying as I want my 3D printer to be quiet in Idle mode.

24 Volt heating cartridge

The heating cartridge inside my hot-end is rated for 12 Volt. It needs to be replaced with a 24 Volt Cartridge. From what I’ve read, on keeping a 12, Volt cartridge, it’s simply not worth the risk. Apparently, the power provided to the 12 Volt Cartridge would quadruple and thus could cause melting the entire heat block. There’s tricks that can be done with PWM sent to the heater but again it’s not worth the risk.

I own a genuine E3D Titan Extruder with E3D hot-end, so I ordered mine directly at e3d-online.com. There are plenty of knock-off on Amazon at $8.99 https://amzn.to/2sDa1s0 (I payed about the same ordering from e3d-online).

Heated Bed

My CoreXY printer runs a 110 Volt heated bed controlled though an SSR so there’s no issue upgrading to 24 Volt (See my instructable on this at instructables.com). The SSR input can handle 3-36 volt.

That said many of the MK2B beds can handle both 12 volt and 24 Volt. It’s just a matter of how to connect the wires.

Cooling Fans

The fan in the power unit is kinda loud so I wanted to replace that right away. I’m a huge fan of the Noctua 40mm cooling fans (their practically noiseless) (Amazon $13.95 https://amzn.to/2HsZdS8).

So I’m replacing all my fans with Noctua Fans. I have 2 80mm fans; one that cools the electronics compartment and one that sits about me stepper which provides for active cooling of my TMC2130 stepper drivers (amazon $15.95 https://amzn.to/2JpABLS).

Then there is the 60mm cooling fan that sits inside the power switching unit so I ordered a 60mm one (Amazon $14.95 https://amzn.to/2Jl49Ke). Small problem with this fan is that it only comes in 60x25mm. It will not fit inside the power unit. Instead it will be mounted on top. Frankly, I was a bit disappointed at how, it is not as quiet as the 40mm ones. Little more measuring showed more than 12 Volt was passed through the fan. It works but looses it’s quiet quality. I’ll need to figure out something to remedy this.

The Board

My CoreXY has been chugging along on a knockoff RAMPS 1.4 controller board. Technically nothing wrong with it and there are ways of modifying the RAMPS 1.4 to handle 24 Volt but, for my printer I decided to replace the RAMPS with a KFB2.0. It’s a cheap alternative that is ready to take on 24 Volt and can even do a little more (Amazon $19.59 https://amzn.to/2M2Q7io).

The nice thing about the KFB 2.0 (or the very similar MKS GEN L) is that there only one pin difference with the RAMPS 1.4 (additional Pin 7 Output). Most of my Marlin configuration can remain the same.

Steppers

The voltage of stepper is entirely controlled by the drivers and therefor don’t need any change. One of the reasons I am moving to 24 volt is because there’s supposed to be more torque on the motors and with the TMC2130 driver’s it’s supposed to get quieter in Spread Cycle mode.

For this upgrade I replaced my Z-axis stepper motor as it was still a 0.4A (from my original build). I’m replacing it with a 1.7A (just because I have one lying around). Amazon $45.99 https://amzn.to/2JBBOms (5 Pack) .

Too much power

As soon as I clicked “Buy Now” button for the 24 Volt Power unit, it dawned on me that there’s a bunch of 12 Volt stuff left on the Printer.

You may have already figured it out when reading about the fan replacements. What I had overseen was the Noctua cooling fan, the parts cooling fan and my LED lighting. All 12 Volt.

Noctua does not sell 24 volt fans (smaller ones that is) but once you go Noctua, you don’t go back. As a matter of fact in this upgrade, I’ve doubled down on more Noctua(s).

There are a few options with the 24 Volt power and 12 volt fans. The case-cooling fan and hot-end cooling fan could be wired in series. Googling that immediately show an article not to do that.

Instead of trying things in series I’m going to use Step down LM2956 Buck converter (Amazon $7.99 https://amzn.to/2M0QppP).

I thought I would need for for the following:

- Case cooling fans/controller fan

- Hot-end cooling fan

- Parts cooling fan

- LED lights

One thing I noticed about connecting the parts cooling fan was that when I would send a command like M106 S127 I would expect to see a lower voltage but when I connected the LM2955 Buck converter, the output remained constant at 24 volt. Someone please explain this to me.

So for the parts cooling fan which is controlled (variably) by the software, I altered the software to not exceed PWM 127 and divide any PWM to the cooling fan by 2 (not entirely 12 Volt but close enough).

Wiring

What you see here (above) is the original wiring. It’s a mess. As part of this upgrade I’m going to pay close attention to wiring and make it all look a bit cleaner.

For the wire management I purchased mini zip ties that allow me to bundle the wires together (and through the board everything is mounted on). Amazon $6.48 https://amzn.to/2HpMrDI

The before picture is above. Below is the new wiring

The old RAMPS 1.4 board uses Dupont connectors. The KFB2.0 does not. It uses JST-XHP 2.54 connectors. This meant a lot of the wires required new crimping.

The JST connectors were all 2/3/4 pin connectors. The following set will do: Amazon $9.87 https://amzn.to/2kRWUyY

If you don’t have one yet, you’ll need a Crimping Tool. I personally use one like these:

Amazon $22.99 https://amzn.to/2sN1fXE

Conclusion

Upgrading to 12 Volt is one of those upgrades that really doesn’t add anything visually to printer. Torque should be higher so technically I can print at higher speeds. Speed and 3D printer in my opinion shouldn’t be used in the same sentence though. I’d rather wait a little longer, than have to deal with bad prints.

The printer is up and running again and it’s operation seems pretty much the same as before.

Certainly the exercise of wiring the printer properly makes things look much better. The CoreXY comes with a drawers style electronics case and no longer looks like the kitchen nick-nack messy drawer. None of this is related to the 24 Volt upgrade.

Would I do it again? Not sure. I’ve always felt my Corvette printer was running on a pinto engine. But, like many things in life you want; once you get them it’s meh.

I’ll keep you posted on whether the upgrade was worth it. In the meantime don’t forget to subscribe and if you like what you read consider supporting me through Patreon at https://www.patreon.com/Core3d_tech